In today’s fast-moving logistics world, warehouse managers face constant pressure to reduce costs, protect goods, and improve operational efficiency. One often-overlooked tool that plays a crucial role in achieving these goals is stretch wrap — a simple yet powerful material that keeps your shipments safe, secure, and professional.

1. Why Stretch Wrap Matters in Every Warehouse

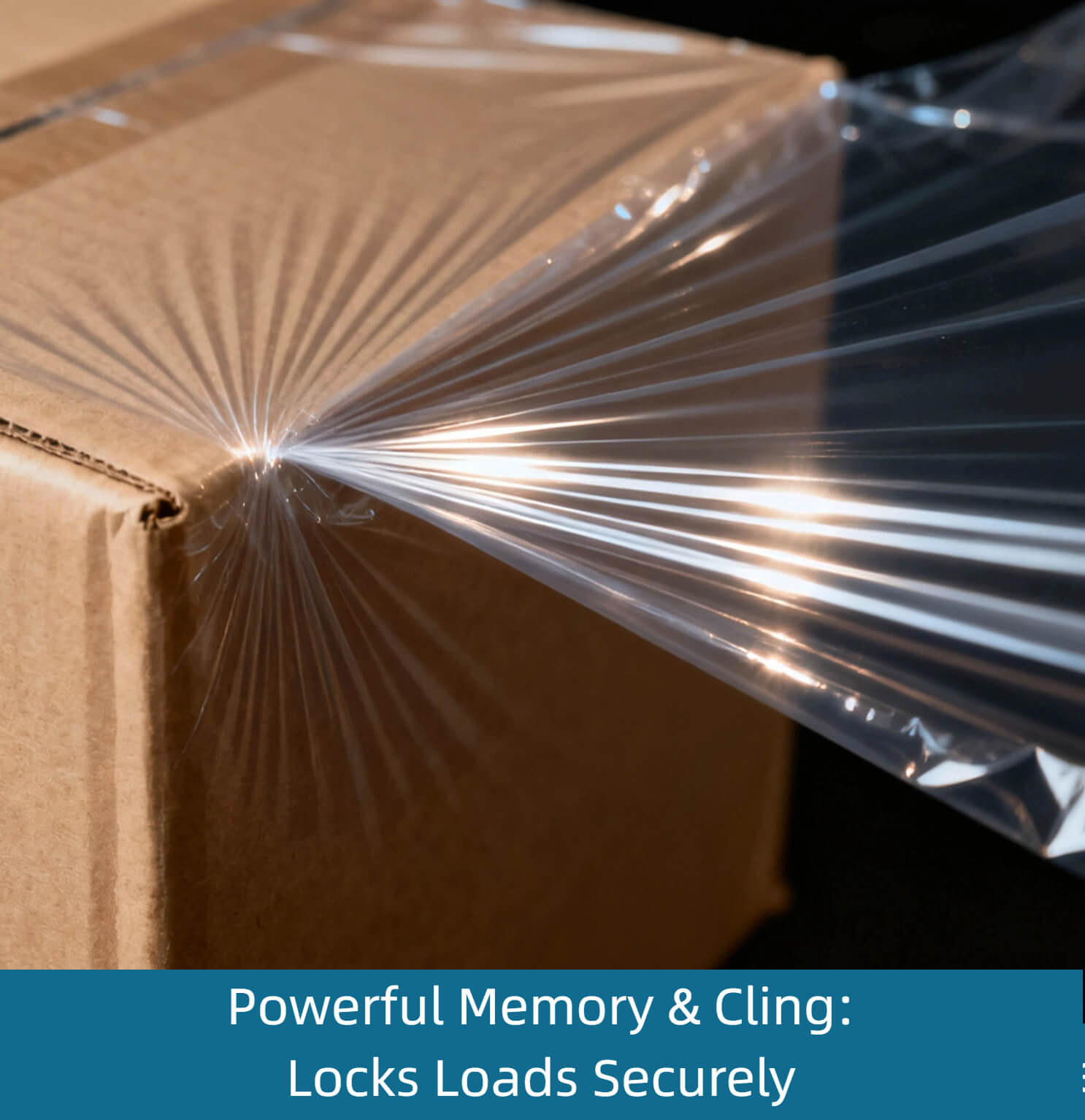

- Reduced product shifting or collapse during transport

- Lower risk of water, dust, or tampering damage

- A cleaner and more organized storage environment

2. Understanding the Types of Stretch Wrap

|

Type |

Best For |

Features |

|---|---|---|

|

Cast Stretch Film |

Standard warehouse use |

Clear, glossy, quiet unwind, good cling |

|

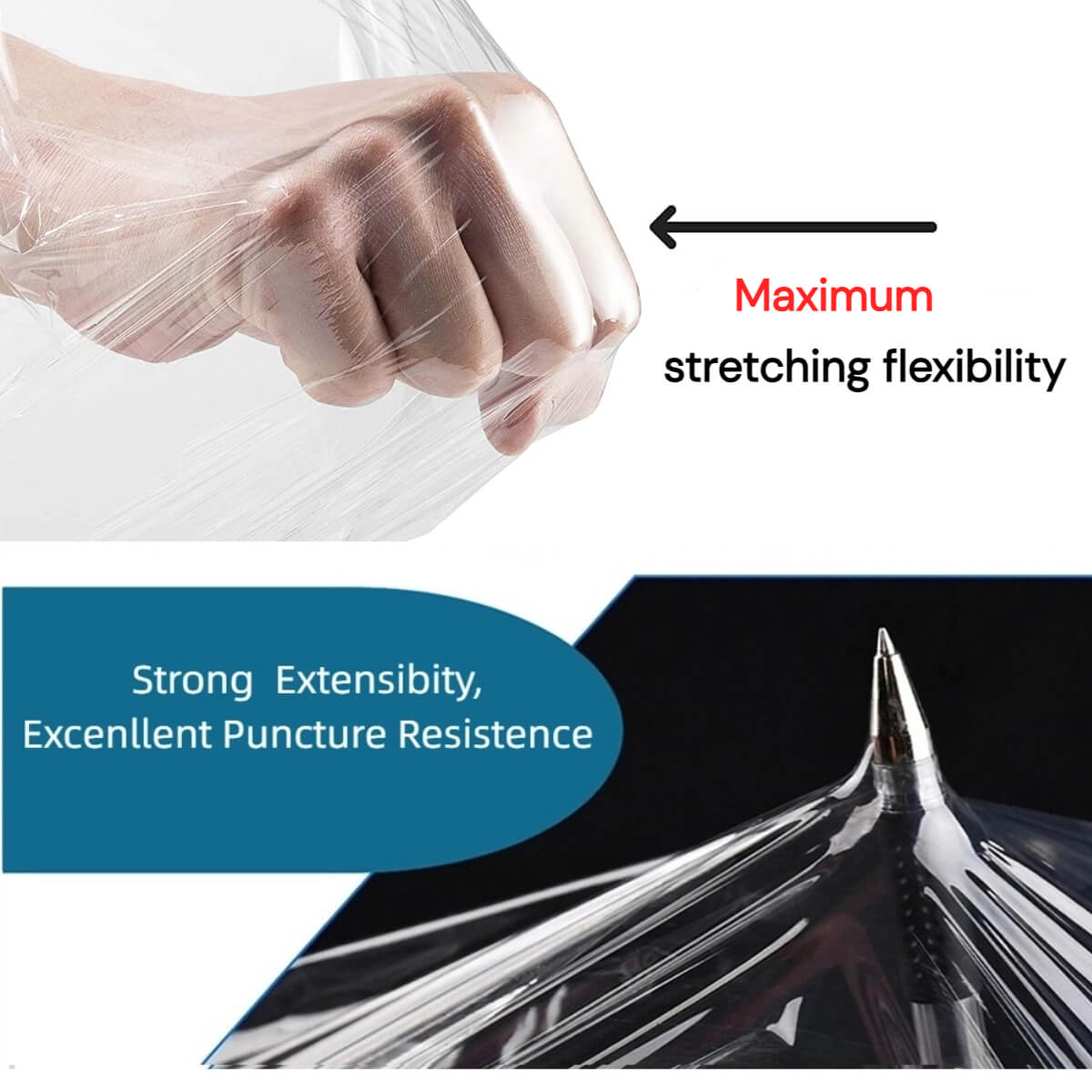

Blown Stretch Film |

Heavy-duty loads |

Strong tear resistance, suitable for irregular pallets |

|

Black Stretch Film |

Confidential shipments |

Blocks UV and hides contents for security |

|

Pre-Stretched Film |

Manual wrapping |

Lighter rolls, easier to apply, less waste |

3. Choosing the Right Gauge and Width

| Gauge | Typical Use |

|---|---|

| 60–70 | Light boxes or uniform pallets |

| 80 | General warehouse and shipping needs |

| 90–120 | Heavy or irregular loads |

4. How the Right Stretch Wrap Saves Money

- Minimize product damage and returns

- Reduce the amount of film used per pallet

- Speed up wrapping time

- Improve load stability, cutting forklift accidents

5. Best Practices for Warehouse Efficiency

- Train staff on proper wrapping techniques — consistent tension and 50% overlap are key.

- Store rolls upright in a cool, dry place to maintain performance.

- Use black stretch film for high-value or confidential shipments.

- Inspect wrapping equipment regularly to avoid film waste.

- Label wrapped pallets clearly to improve warehouse workflow.

6. Sustainable Options for Modern Warehouses

As eco-friendly packaging becomes a priority, many suppliers now offer recyclable and biodegradable stretch films. Switching to eco film can reduce carbon footprint, comply with sustainability goals, and enhance your brand’s image with customers.

7. Where to Source Reliable Stretch Film

Look for suppliers that offer multiple gauges and widths, consistent film quality, bulk pricing, and fast delivery. Buying directly from manufacturers like YXX-Tech ensures better pricing, fresher inventory, and technical support.

Conclusion

Stretch wrap may seem like a small detail in warehouse operations, but it plays a critical role in efficiency, cost savings, and product protection. By choosing the right film and applying it correctly, warehouse managers can achieve smoother logistics, happier customers, and a stronger bottom line.

0 comentarios