Shipping and logistics costs are a major concern for warehouses, distributors, and e-commerce businesses. One of the simplest yet most effective ways to reduce both shipping costs and product damage is by using stretch film—also known as pallet wrap or stretch wrap. Below we explain how stretch film improves load stability, protects goods, and delivers measurable savings.

1. Maximized Load Stability

Stretch film tightly binds multiple boxes or items together, creating a single, secure unit. This prevents shifting or toppling during transportation, especially on long-distance or international shipments.

- Keeps pallets compact and stable — reducing risk of collapse during transit.

- Minimizes product slippage — fewer broken or damaged items.

- Reduces insurance claims & returns — lower operational costs.

2. Lower Packaging Material & Freight Costs

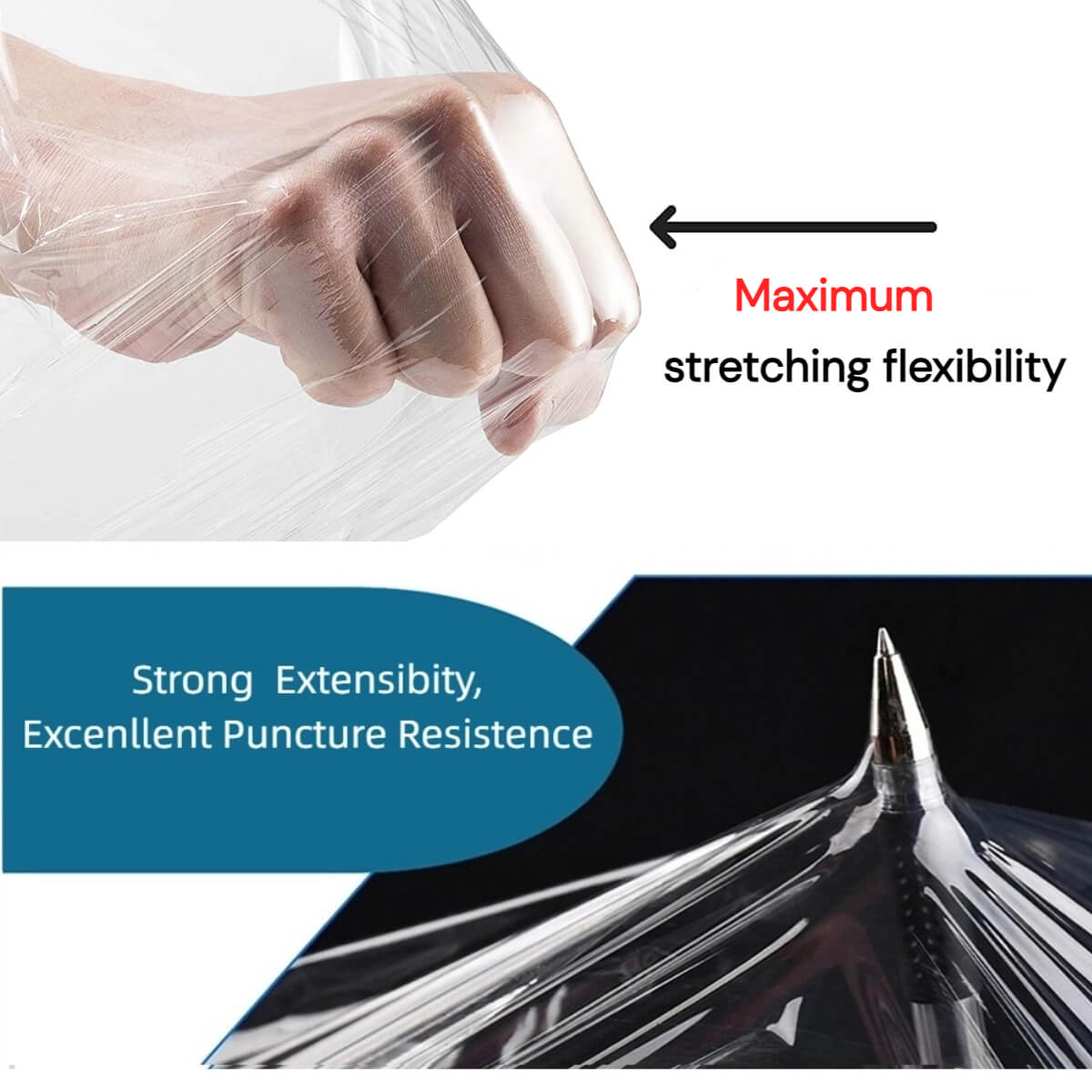

Compared with heavier packaging solutions, stretch film is lightweight and highly elastic, which means you can cover more area with less material.

- High-elasticity film stretches farther — fewer rolls used per pallet.

- Reduced packaging weight helps lower freight charges, especially for shipping calculated by weight.

- Less time and fewer materials (vs. strapping or excessive cardboard) = lower per-shipment cost.

3. Protection from Dust, Moisture, and Tampering

Stretch film acts as an effective protective barrier:

- Dust & moisture protection — keeps goods clean in storage and transit.

- Black/opaque options (see black stretch film) provide privacy for high-value shipments.

- Tamper-evident wrapping deters unauthorized access and reduces pilferage risk.

4. Improved Handling Efficiency & Worker Safety

Pallets wrapped with film are simpler and safer to move with forklifts or pallet jacks. Faster wrapping processes (manual or machine) improve throughput in packing and loading areas.

- Reduced rework when loads shift or items fall during handling.

- Faster loading and unloading times — boosts warehouse productivity.

- Safer work environment with fewer incidents related to unstable loads.

5. Sustainability & Waste Reduction

Modern stretch films offer sustainability benefits that also affect cost-efficiency:

- Thinner, high-performance films use less plastic while providing equal or better holding strength.

- Recyclable options reduce landfill waste when proper recycling programs are in place.

- Using the right gauge and wrap technique minimizes material waste and total cost per pallet.

Best Practices to Maximize Savings

- Choose the correct gauge: heavier loads need higher-gauge film for fewer wraps and better stability.

- Use machine wrap where possible: automated wrapping delivers consistent tension and reduced film usage.

- Train staff: proper wrapping technique (pre-stretch, overlap, top & bottom reinforcement) reduces rework.

- Buy in bulk: bulk stretch film rolls lower unit cost and reduce procurement frequency.

Conclusion

Stretch film is a cost-effective, versatile solution that reduces shipping damage and lowers overall logistics costs. By improving load stability, protecting shipments, and enabling faster handling, the right stretch film strategy pays back quickly.

Ready to reduce your shipping costs? Explore our range of industrial stretch films — clear, black, and extra-wide — at YXX-Tech or visit our stretch film collection to find the right roll for your operation.

0 comentarios