What is Stretch Wrap? (The Ultimate Protective Solution)

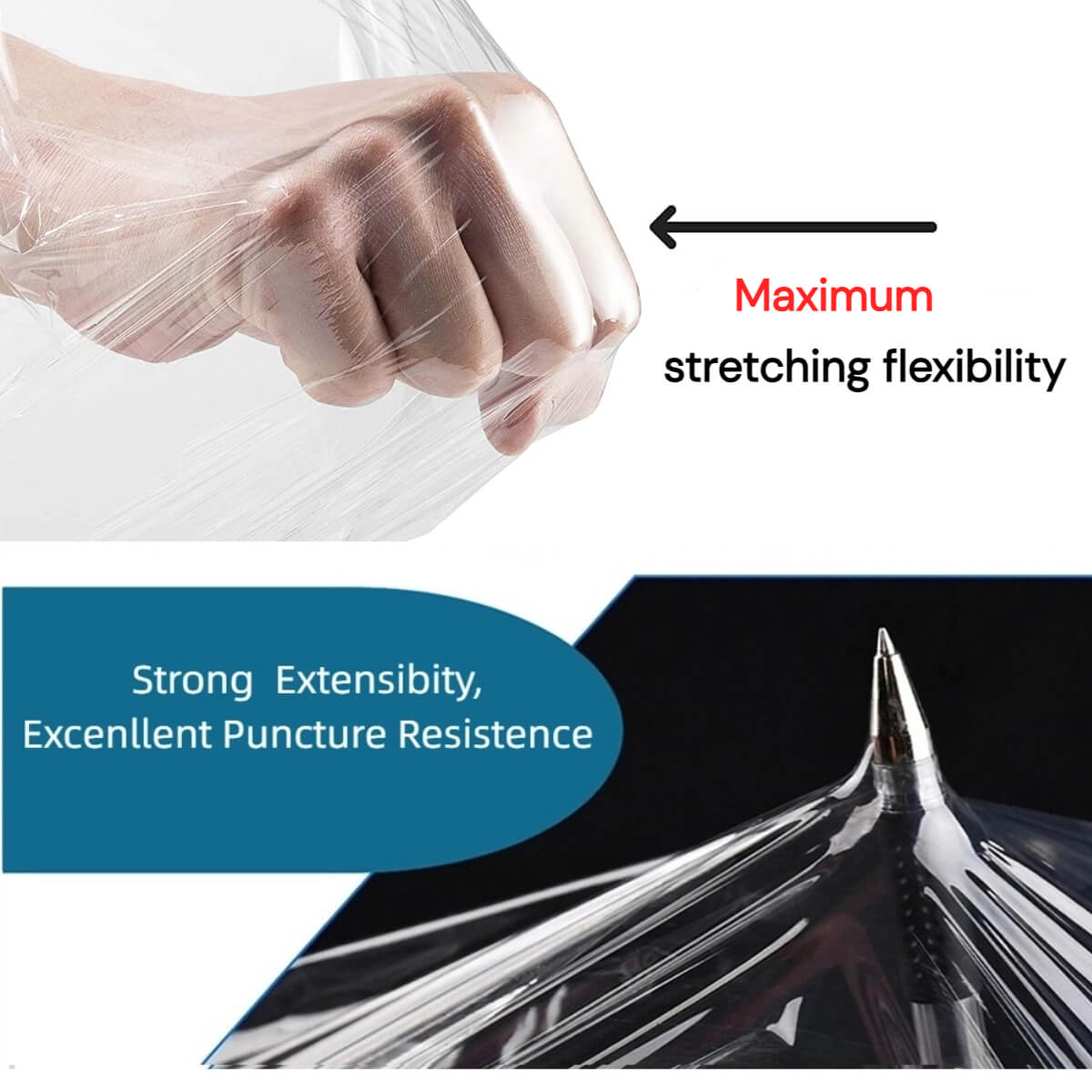

Stretch wrap (or stretch film) is a highly elastic plastic film made from linear low-density polyethylene (LLDPE) that clings to itself when stretched. This innovative packaging material creates a secure, protective layer around items without needing adhesives or heat.

Key Characteristics:

-

Self-adhering through tension

-

Highly flexible and durable

-

Available in various thicknesses (gauges)

-

Transparent or opaque options

Top 5 Industrial & Commercial Applications

-

Pallet Stabilization - Secures loads up to 2,500 lbs for safe transport

-

Furniture Protection - Guards against scratches during moves (home/office)

-

Retail Bundling - Groups products without boxes (e.g., water bottles, building materials)

-

Warehouse Organization - Weatherproofs outdoor storage

-

Food Safety - FDA-approved options for perishable goods

Stretch Wrap Varieties Compared

| Type | Best For | Key Advantage |

|---|---|---|

| Hand Film | Small businesses, occasional use | No equipment needed |

| Machine Film | High-volume operations | 3-5x faster application |

| Pre-Stretched | Labor-intensive jobs | Reduces worker fatigue by 40% |

| VCI Film | Metal parts | Prevents corrosion |

| UV-Resistant | Outdoor storage | 6-12 month sun protection |

Why 90% of Businesses Choose Stretch Wrap

✔ Cost Savings - Uses 30% less material than shrink wrap

✔ Damage Prevention - Reduces shipping losses by up to 60%

✔ Space Optimization - Compacts loads by 15-20% vs. strapping

✔ Sustainability - Recyclable options (look for LLDPE #4 symbol)

✔ Versatility - Works on irregular shapes other wraps can't secure

Stretch Wrap vs. Shrink Wrap: Key Differences

Stretch Wrap:

-

Applied at room temperature

-

Sticks through mechanical tension

-

Ideal for load stabilization

-

Lower material cost

Shrink Wrap:

-

Requires heat application

-

Forms airtight seals

-

Better for retail packaging

-

Higher equipment costs

Pro Tips for Maximum Effectiveness

-

Proper Tension - Stretch to 150-200% of original length (not beyond)

-

Overlap Pattern - 50% overlap for heavy loads, 30% for light items

-

Corner Protection - Use edge guards on sharp corners

-

Climate Considerations - Cold weather? Use specialty low-temp film

-

Eco-Friendly Disposal - Many municipal recycling programs accept clean stretch film

Emerging Trends in Stretch Film Technology

-

Nano-layer films - 30% stronger at same thickness

-

Bio-based resins - Up to 50% plant-derived materials

-

Smart films - Color-changing indicators for tampering/temperature

-

Automated systems - AI-powered wrappers that optimize film usage

Choosing Your Ideal Stretch Wrap

Consider these 4 factors:

-

Load Weight (<1,000 lbs = 80 gauge; >1,000 lbs = 100+ gauge)

-

Application Method (Hand vs machine vs automated)

-

Environmental Conditions (Indoor/outdoor, temperature extremes)

-

Visibility Needs (Clear for inspection vs opaque for security)

"We reduced our packaging costs by 22% simply by switching to the right stretch film for our operation." - Sarah K., Logistics Manager

Need stretch wrap for your warehouse or eCommerce business?

👉 Explore our premium selection of stretch film – available in various widths, thicknesses, and colors for every application.

📘 Want the full guide? Click here to download 10 Common Stretch Wrap Mistakes & How to Avoid Them

0 comments