Warehouse Efficiency Tips: Using Stretch Wrap for Pallet Stability

Efficient warehouse operations rely on more than just inventory management and fast order fulfillment. One often overlooked factor is pallet stability. Properly securing palletized goods not only prevents damage but also enhances warehouse efficiency, reduces labor costs, and ensures safe transportation. A simple yet effective solution for this is stretch wrap (also known as pallet wrap or stretch film).

Why Pallet Stability Matters in Warehouses

Unstable pallets can create serious issues for warehouses and logistics operations:

- Product Damage: Shifting goods can crush items or cause spills, leading to costly replacements.

- Safety Hazards: Leaning or collapsing pallets increase the risk of workplace injuries.

- Inefficient Space Use: Unstable pallets make stacking difficult, wasting valuable storage space.

- Shipping Delays: Damaged pallets slow down loading, unloading, and delivery processes.

By using stretch wrap from YXX Tech correctly, warehouses can secure goods, protect inventory, and improve workflow efficiency.

Key Benefits of Stretch Wrap for Pallets

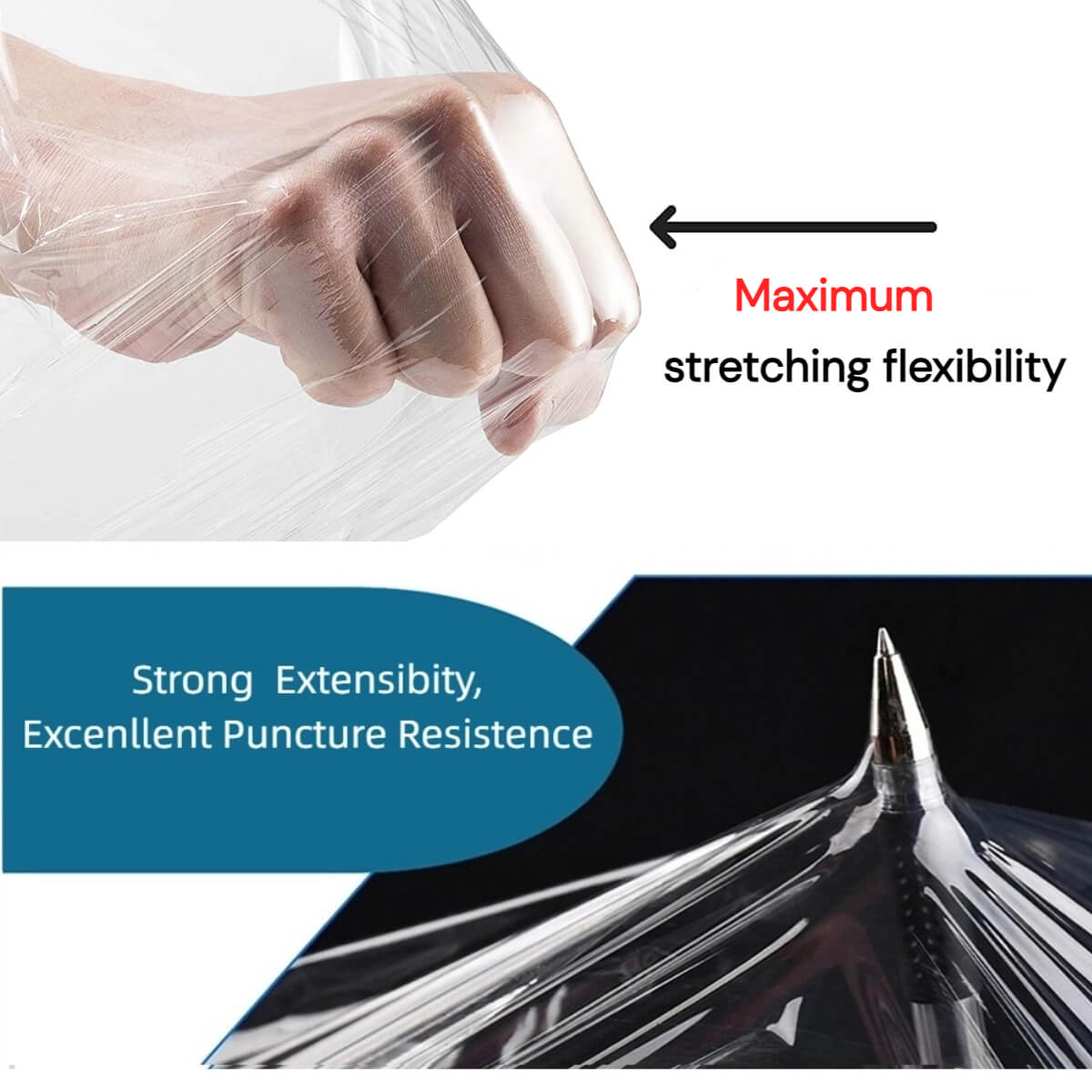

- Enhanced Pallet Stability: Stretch wrap tightly binds items together, preventing shifting during transport or storage.

- Protection from Dust and Moisture: Wrap acts as a barrier against dirt, water, and contaminants.

- Cost Savings: Minimizes product damage, reducing replacement costs.

- Versatility: Ideal for boxes, cartons, and irregularly shaped products.

- Better Warehouse Organization: Wrapped pallets are easier to stack and move using forklifts or pallet jacks.

Expert Tips for Using Stretch Wrap Efficiently

1. Select the Right Stretch Wrap

- Gauge & Thickness: Use thicker film for heavier pallets to ensure stability.

- Color Options: Black wrap hides contents and offers UV protection; clear wrap allows product visibility.

- Hand vs. Machine Wrap: High-volume warehouses benefit from machine wrapping; smaller operations can use hand wrap rolls.

2. Wrap Strategically

- Start at the pallet base to secure the bottom layer.

- Overlap each layer slightly to improve grip.

- Finish at the top to hold taller items firmly in place.

3. Avoid Overwrapping

Excessive film wastes material and increases costs. A few well-placed layers often provide sufficient stability.

4. Train Warehouse Staff

Proper wrapping techniques are crucial for safety and efficiency. Conduct staff training to ensure consistent pallet security.

5. Regular Inspection

Even wrapped pallets can loosen over time. Inspect pallets periodically to maintain stability and avoid accidents.

Conclusion

Stretch wrap from YXX Tech is an essential tool for modern warehouses and logistics operations. By selecting the right type, applying correct techniques, and training staff, warehouses can improve pallet stability, reduce product damage, and streamline shipping and storage processes.

Invest in high-quality stretch wrap today and turn pallet protection into a competitive advantage for your warehouse operations.

0 comments