The stretch film industry is evolving rapidly, driven by sustainability demands, technological advancements, and shifting logistics needs. As businesses seek cost-effective, eco-friendly, and high-performance packaging solutions, understanding the latest trends can help you stay ahead.

In this blog post, we’ll explore:

✔ Key market growth projections for stretch film in 2025

✔ Latest technological innovations, including ultra-thin and smart films

✔ Sustainability trends, such as recyclable and bio-based materials

✔ Industry-specific applications boosting demand

✔ How to choose the right stretch film for your business

1. Stretch Film Market Growth in 2025

The global stretch film market is projected to reach $67.1 billion by 2032, growing at a CAGR of 5.27% from 20252. Key factors driving this expansion include:

-

E-commerce boom: Increased demand for secure packaging in logistics.

-

Automation in warehouses: More companies adopt machine stretch wrapping for efficiency.

-

Food & beverage sector growth: Stretch film ensures freshness and tamper-proofing.

Regional Insights:

-

Asia-Pacific dominates with 36.68% market share (2024) due to manufacturing growth2.

-

North America sees strong demand from retail and cold chain logistics7.

2. Technological Innovations in Stretch Film

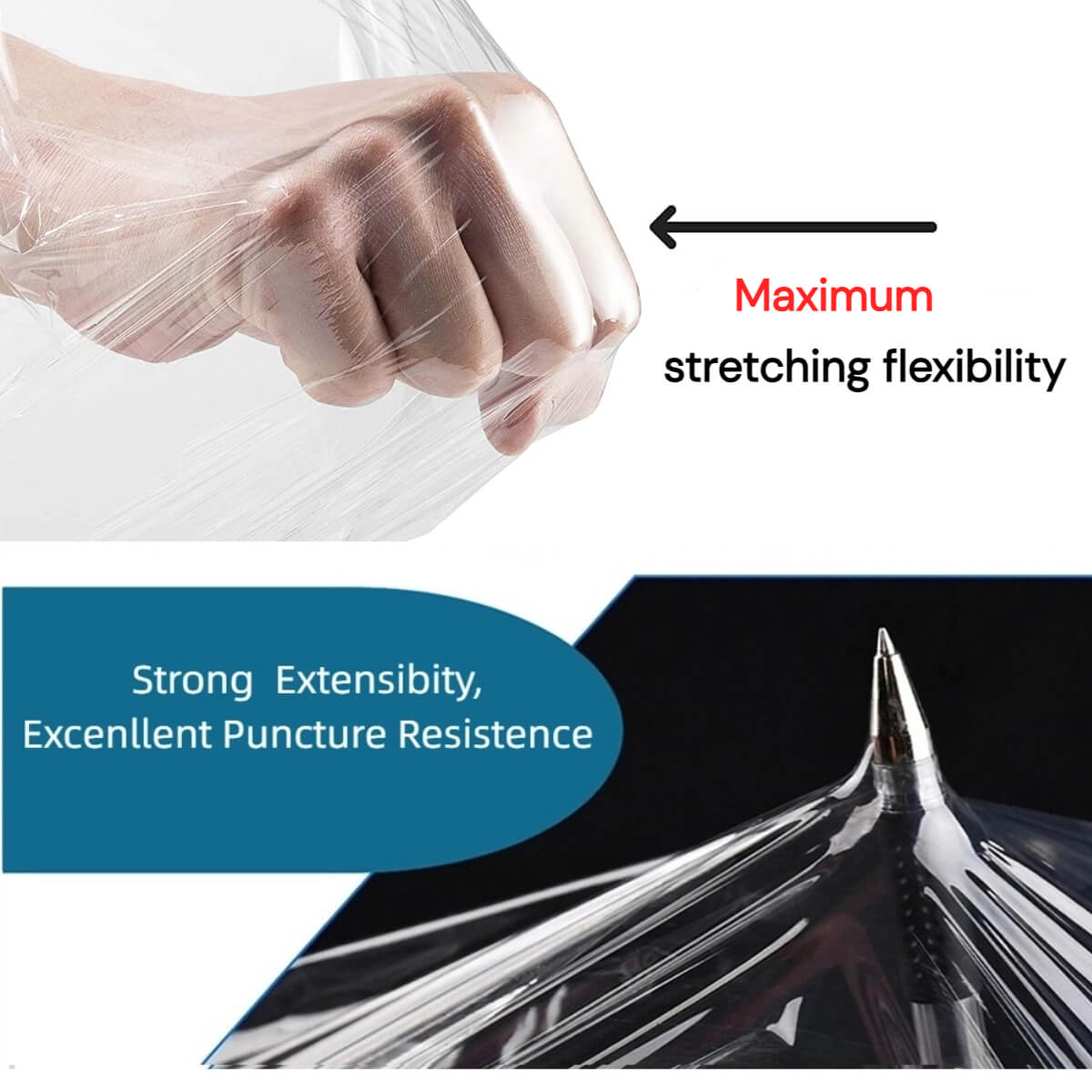

A. Ultra-Thin & High-Performance Films

-

Reifenhäuser’s EVO Ultra Stretch technology produces 18µm PE films, the thinnest yet strongest on the market, reducing material use while maintaining durability1.

-

Nano stretch films (55-layer polymers) offer superior puncture resistance with 30% less material2.

B. Smart Stretch Film (IoT-Enabled Packaging)

-

RFID & sensor-integrated films track shipments in real-time, improving supply chain visibility8.

-

Self-healing films automatically repair minor tears, reducing waste8.

3. Sustainability: The Push for Eco-Friendly Films

With plastic regulations tightening, manufacturers are innovating:

-

Mono-material PE films: Fully recyclable, replacing multi-layer composites1.

-

Bio-based & biodegradable films: Emerging as alternatives to traditional LDPE10.

-

Pre-stretch technology: Reduces film usage by 30%, lowering costs and waste2.

Did you know?

➜ SIBUR’s new mLLDPE grade enhances recyclability while maintaining strength, ideal for FMCG packaging10.

4. Industry-Specific Demand Surges

| Industry | Key Use Case | Growth Driver |

|---|---|---|

| Logistics & E-commerce | Pallet wrapping for secure shipping | Rising online retail & automation |

| Food & Beverage | Fresh produce packaging | Demand for extended shelf life |

| Agriculture | Silage & hay bale wrapping | Increased farming efficiency |

| Construction | Heavy material bundling | Infrastructure development |

5. How to Choose the Right Stretch Film in 2025

When selecting stretch film, consider:

✅ Load Type (lightweight vs. heavy-duty)

✅ Thickness (15µm-80µm for different applications)

✅ Material (LLDPE for stretchability, PP for clarity)

✅ Sustainability (recyclable, bio-based options)

Pro Tip:

➜ Machine-grade films save 40% more material than manual films, ideal for high-volume operations2.

Final Thoughts: The Future of Stretch Film

The stretch film industry in 2025 is shaped by:

✔ Thinner, stronger films (like EVO Ultra Stretch & nano films)

✔ Smart packaging (IoT, RFID tracking)

✔ Sustainability shifts (mono-PE, biodegradable options)

For businesses, adopting these innovations can cut costs, improve efficiency, and meet eco-compliance.

Need the best stretch film for your needs? Explore our Shopify store’s selection for high-performance, sustainable options!

Optimize your packaging strategy today—stay ahead with the latest in stretch film technology!

📘 Want the full guide? Click here to download Market Growth: Smart Tech & Eco Solutions

0 comments