When it comes to pallet wrapping and load stability, stretch film is one of the most essential packaging materials in warehouses, logistics, and manufacturing. But not all stretch film is created equal. To choose the right film, it’s important to understand three key factors: gauge, thickness, and strength.

In this article, we’ll break down the science behind stretch film and help you select the right option for your packaging needs.

1. What Is Stretch Film?

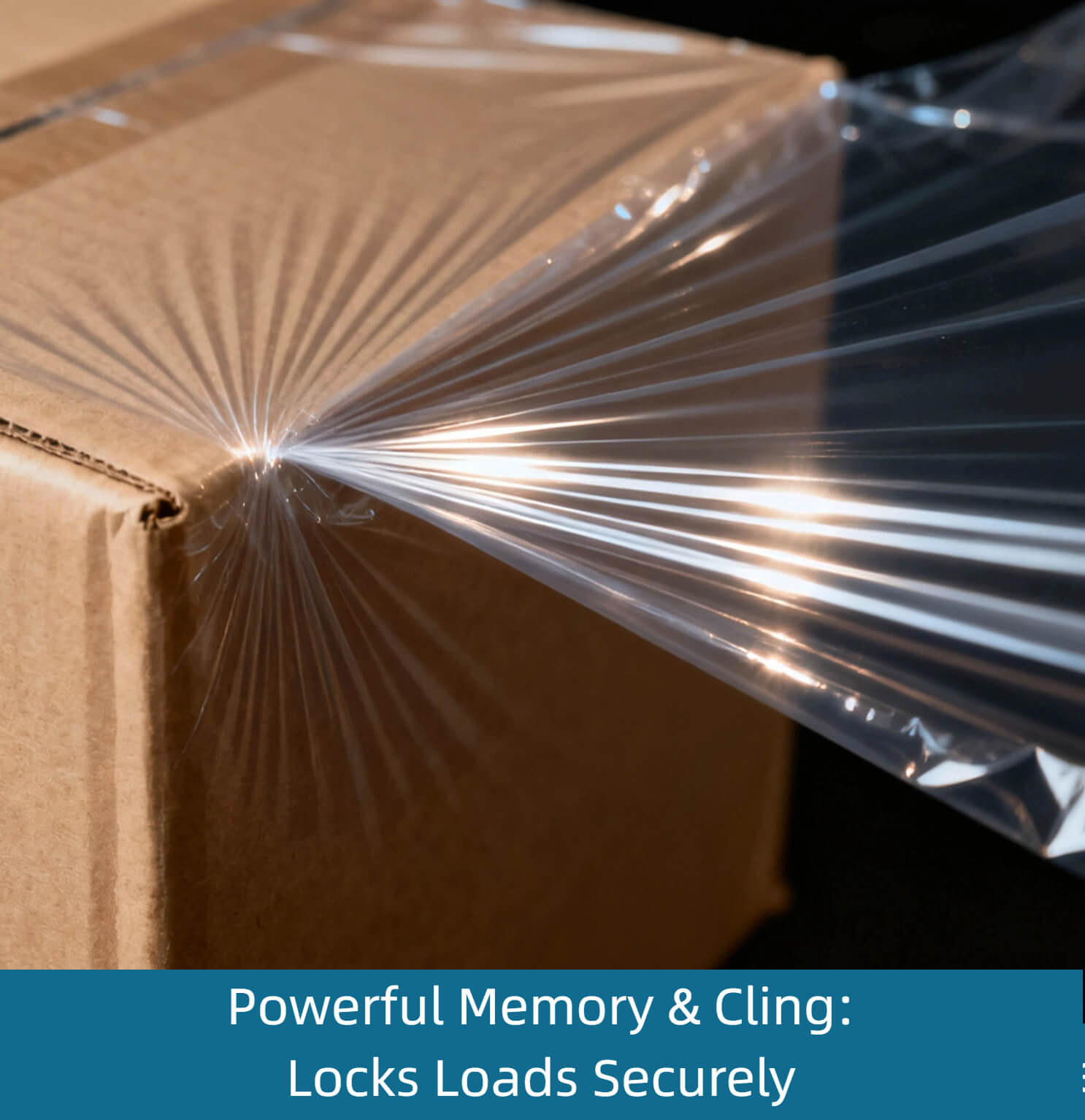

Stretch film (or stretch wrap) is a highly stretchable plastic film made from linear low-density polyethylene (LLDPE). It is applied around products—often on pallets—to secure and protect them during storage or shipping.

The film clings tightly to itself, providing load stability and resistance against dust, moisture, and tampering.

2. Understanding Film Gauge and Thickness

Gauge

-

Gauge is the traditional way of measuring stretch film thickness.

-

1 gauge = 0.254 microns (or 0.01 mils).

-

Example: An 80-gauge stretch film is about 20 microns thick.

Microns / Mils

Today, many suppliers prefer microns or mils for accuracy:

-

Microns (µm): 1 micron = 0.001 mm.

- Mils: 1 mil = 0.001 inch.

Why It Matters

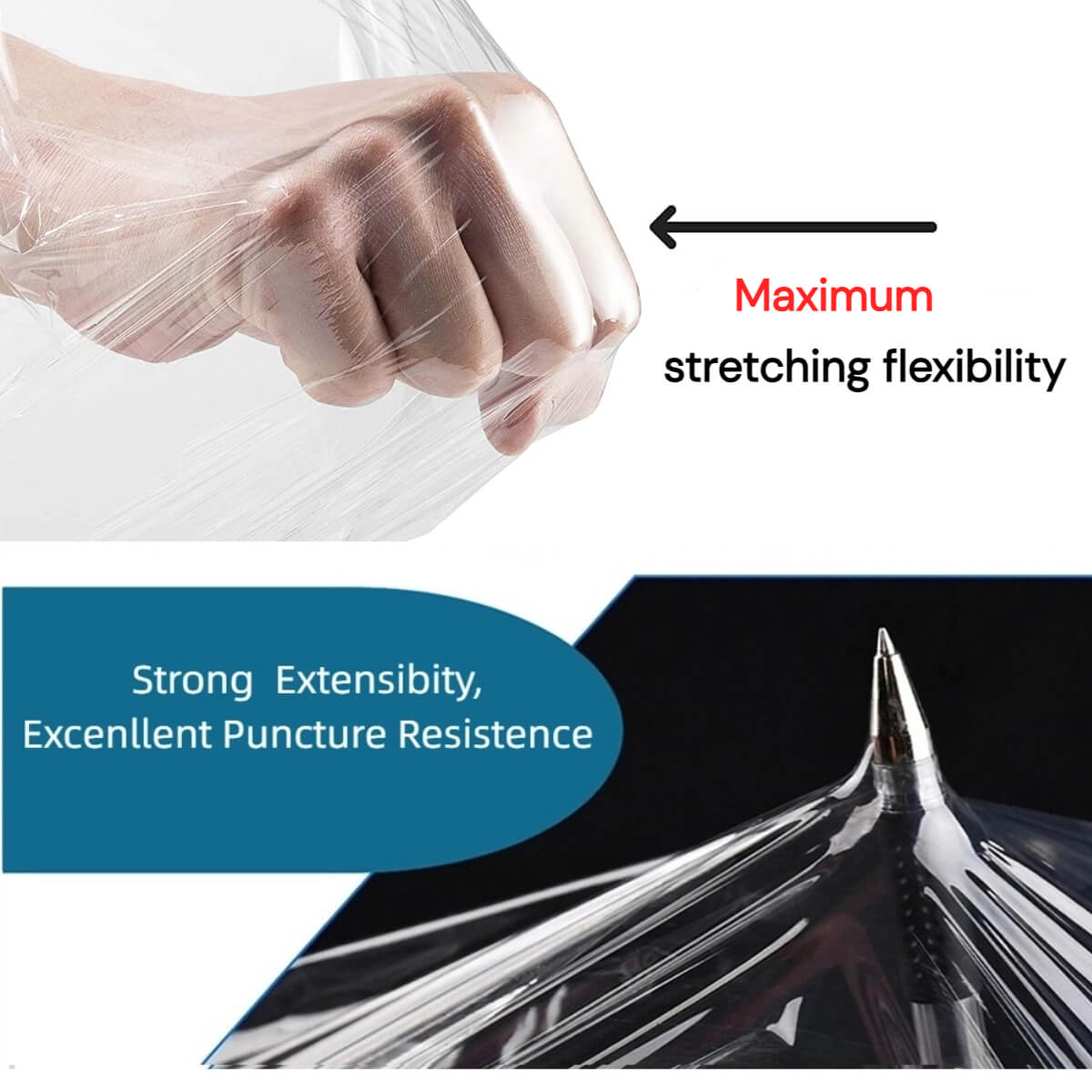

Thicker films (higher gauge/microns) provide better puncture resistance and strength, while thinner films reduce material cost and waste. Choosing the right thickness balances performance and efficiency.

3. Stretch Film Strength and Performance

Strength depends on more than just thickness. Three main factors play a role:

-

Tensile Strength – The maximum load the film can handle without breaking.

-

Puncture Resistance – How well the film withstands sharp edges or corners.

-

Stretchability (Elongation) – How far the film can stretch before tearing, which impacts load containment and cost savings.

Modern stretch films use resin technology and multi-layer extrusion to achieve high strength even at lower thicknesses—helping reduce overall packaging costs.

4. Choosing the Right Stretch Film for Your Application

-

Lightweight Loads (under 500 lbs): 55–63 gauge film (12–16 microns).

-

Medium Loads (500–1,200 lbs): 70–80 gauge film (17–20 microns).

-

Heavy Loads (over 1,200 lbs): 90+ gauge film (23+ microns).

-

Irregular or Sharp Loads: Use higher puncture-resistant films or reinforced options.

If sustainability is a priority, consider pre-stretched films, which use less material while maintaining strength.

5. Final Thoughts

Stretch film might look simple, but the science behind gauge, thickness, and strength makes a big difference in protecting your products and optimizing packaging costs.

By selecting the right film, businesses can:

-

Improve load stability

-

Reduce product damage

-

Lower material waste

-

Boost warehouse efficiency

👉 Looking for high-performance stretch wrap for your warehouse or shipping needs? Shop stretch film rolls at YXX Tech.

📘 Want the full guide? Click here to download The Science Behind Stretch Film: Gauge, Thickness, and Strength Explained

0 comments