Why Stretch Wrap Film is Essential for Shipping & Storage

Every year, businesses lose millions due to damaged goods, unstable loads, and inefficient packaging. Stretch wrap film is a smart solution for securing pallets, protecting inventory, and optimizing logistics. Used by warehouses, manufacturers, movers, and distributors, this versatile plastic wrap:

- ✔ Prevents shifting & damage during transit

- ✔ Shields against dust, moisture, and tampering

- ✔ Reduces packaging costs vs. alternatives like strapping or tape

- ✔ Improves warehouse efficiency with fast, secure wrapping

Whether you’re shipping pallets, furniture, or small bundles, choosing the right stretch wrap can save time, money, and hassle.

Top 5 Uses of Stretch Wrap in Logistics & Warehousing

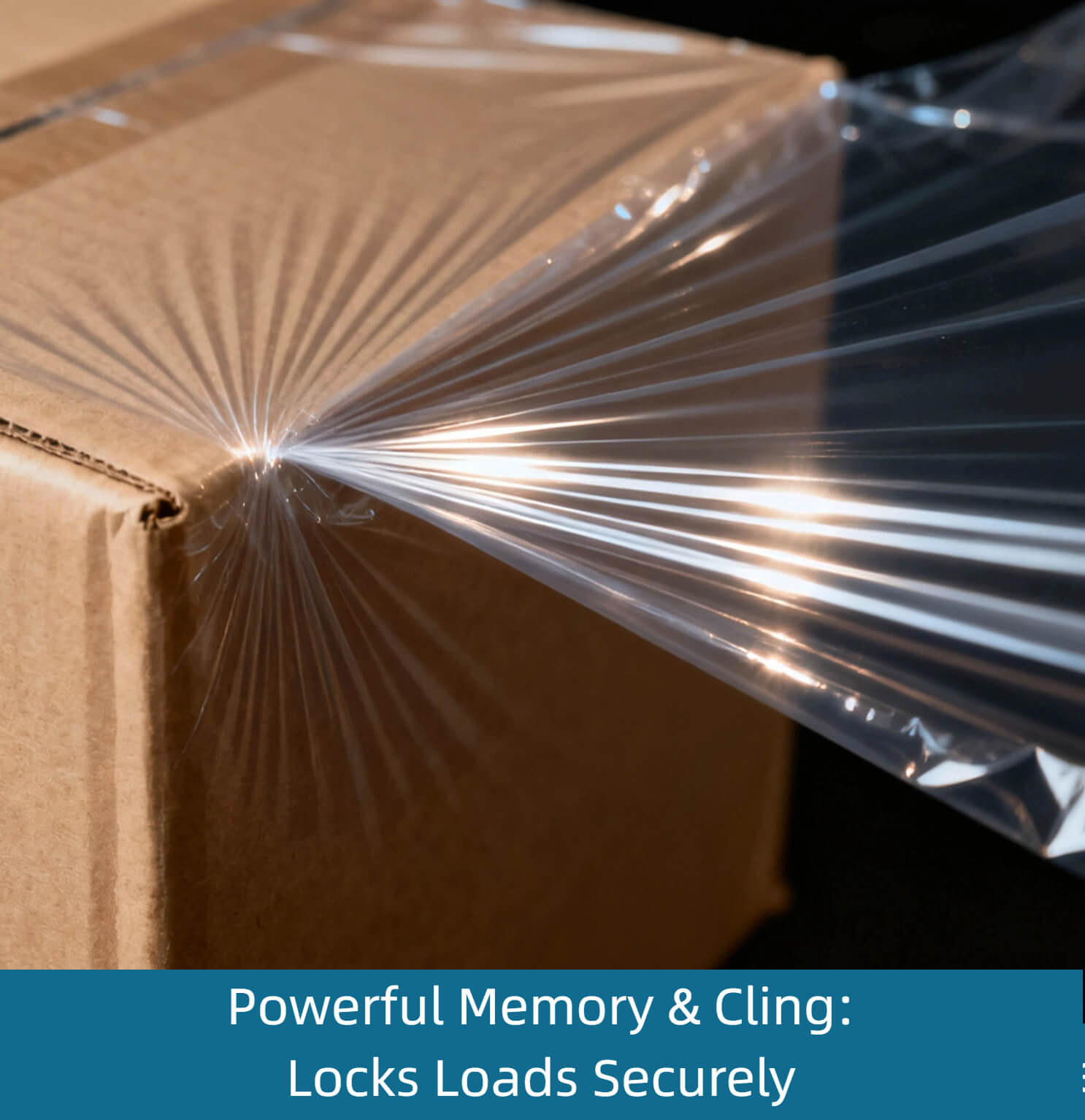

1. Pallet Stabilization & Load Security

- 🔹 Prevents load collapses during transport

- 🔹 Reduces product damage & returns

- Ideal for: Warehouses, distribution centers, manufacturers

2. Protection Against Dust, Dirt & Moisture

- 🔹 Water-resistant barrier keeps goods clean

- 🔹 Prevents mold & spoilage for food, pharmaceuticals, and sensitive products

3. Tamper Evidence & Privacy with Colored Wrap

- 🔹 Black or opaque film hides contents (great for high-value shipments)

- 🔹 Tamper-proof seal deters theft

4. Bundling Boxes & Improving Warehouse Efficiency

- 🔹 Groups small items for easier handling

- 🔹 Speeds up inventory management

5. Furniture & Equipment Protection for Moving & Storage

- 🔹 Prevents scratches & dents

- 🔹 Keeps items dust-free in long-term storage

Key Benefits of Stretch Wrap Film

| Advantage | Why It Matters |

|---|---|

| 💰 Cost-Effective | Cheaper than strapping or shrink wrap |

| ⚡ Fast Application | Manual or machine wrapping in seconds |

| 🔄 Recyclable Options | Eco-friendly films available |

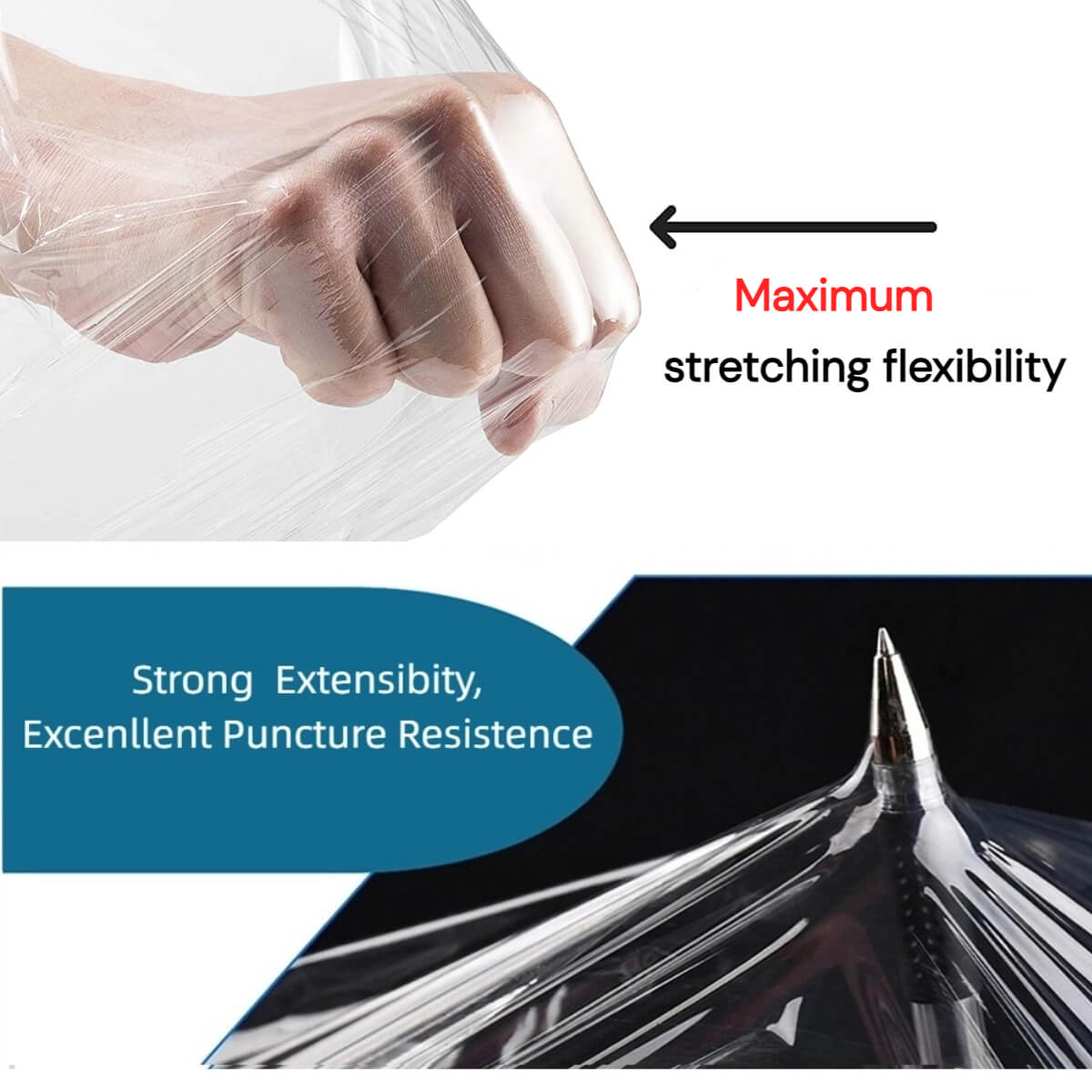

| 🔒 Superior Load Stability | Stretches up to 300% for a tight hold |

| 🛡️ Weather & UV Resistance | Protects outdoor-stored goods |

Types of Stretch Wrap & How to Choose

| Type | Best For | Key Features |

|---|---|---|

| Hand Stretch Film | Small loads, manual use | Lightweight, easy to apply |

| Machine Stretch Film | High-volume packaging | Thicker, stronger, automated |

| Colored Stretch Wrap | Security, branding | Conceals contents, UV protection |

| Pre-Stretched Film | Cost savings | Uses less material, high strength |

How to Select the Right Stretch Wrap

- ✅ Light loads (under 1,000 lbs): 50–60 gauge

- ✅ Medium loads (1,000–2,500 lbs): 70–80 gauge

- ✅ Heavy-duty loads (2,500+ lbs): 90+ gauge + reinforced edges

Pro Tips for Optimal Stretch Wrapping

- Start at the Base – Wrap bottom layers tightly for stability.

- Overlap by 50% – Ensures no gaps in coverage.

- Use Corner Boards – Protects sharp edges from tearing film.

- Try Pre-Stretched Film – Reduces waste & costs.

- Store Properly – Keep in a cool, dry place to maintain cling.

FAQs: Stretch Wrap Film Explained

Q: Can stretch wrap be used outdoors?

A: Yes! UV-resistant stretch wrap (often colored) is ideal for outdoor storage.

Q: Hand vs. machine stretch wrap – what’s the difference?

A: Hand wrap = Thinner, easier for manual use. Machine wrap = Thicker, designed for high-speed packaging lines.

Q: Is stretch wrap recyclable?

A: Many options are 100% recyclable LDPE plastic — check for eco-friendly films.

Upgrade Your Packaging Today!

Don’t risk damaged shipments, wasted time, or lost profits — invest in high-performance stretch wrap tailored to your needs.

- 📦 Bulk discounts available

- ⚡ Fast shipping nationwide

- 🛡️ Guaranteed load security

Visit YXX Tech to browse our full range of stretch wrap products, request a quote, or contact our packaging experts for custom solutions.

📘 Want the full guide? Click here to download Types, Uses & Best Practices of Stretch Wrap

0 comments